Understanding the Relevance of Stretch Wrapper Repair for Ideal Product Packaging Effectiveness

Stretch wrappers play an important role in making certain packaging performance across different markets. Nonetheless, their performance can be jeopardized by common issues that arise with time. Overlooking repair work can result in significant operational troubles and financial repercussions. Understanding the indicators that suggest upkeep is required is vital for maintaining productivity. This raises the inquiry of just how firms can efficiently manage their stretch wrapper maintenance to protect against disruptions and preserve quality.

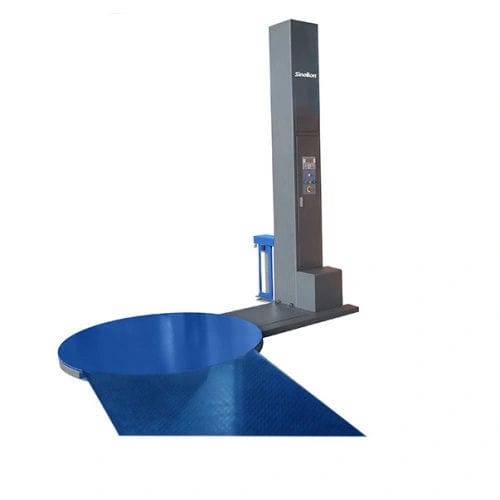

The Duty of Stretch Wrappers in Packaging Performance

Stretch wrappers function as important parts in the packaging procedure, significantly boosting performance in various markets. These devices make use of stretch film to secure products on pallets, decreasing movement during transportation and storage space. By securely covering things, stretch wrappers secure them from damages, moisture, and contamination, ensuring they arrive at their destination intact.In addition to protecting items, these wrappers enhance the product packaging operations. Automated stretch covering systems considerably raise output, decreasing time and labor expenses related to manual product packaging. The constant application of tension in the covering procedure also maximizes product usage, resulting in set you back financial savings and decreased waste.Moreover, stretch wrappers can be adapted to suit various product dimensions and forms, offering adaptability in product packaging operations. This versatility enables business to enhance their general productivity, maintain high criteria of quality assurance, and enhance customer fulfillment through reputable distribution of well-packaged products.

Common Problems That Affect Stretch Wrapper Efficiency

Packaging effectiveness can be substantially prevented by various issues that impact stretch wrapper efficiency. One common trouble is irregular stress throughout the wrapping process, which can lead to inadequate lots stability (stretch wrapper repair). Furthermore, malfunctioning sensors may stop working to spot the tons elevation, causing incorrect wrapping and thrown away products. Tear and put on on parts such as belts and rollers can also interrupt the smooth procedure of the maker, creating hold-ups and prospective damages to products. An additional issue is the quality of the stretch movie itself; below average products can tear easily or fall short to stick correctly to the lots. Routine maintenance is necessary to determine and correct these issues before they rise. Ultimately, guaranteeing peak performance of stretch wrappers not only boosts product packaging effectiveness however additionally maintains product honesty throughout the supply chain. Attending to these typical issues is crucial for preserving reliable product packaging operations

The Financial Impact of Ignoring Stretch Wrapper Services

Neglecting stretch wrapper repairs can bring about significant economic effects for organizations. Enhanced product packaging costs and long term downtime outcome in productivity loss, ultimately impacting the bottom line. Resolving these repair work quickly is important to keep functional effectiveness and cost-effectiveness.

Enhanced Packaging Prices

Gradually, falling short to deal with needed repairs on stretch wrappers can lead to considerable monetary repercussions for organizations. As equipment malfunctions or uses down, product packaging efficiency diminishes, causing increased product use. This can materialize as the demand for even more stretch movie to protect loads effectively, elevating general packaging prices. Additionally, inadequately wrapped items might lead to damage throughout transportation, requiring additional expenditures for replacements and customer settlement. Firms might likewise find themselves investing in expedited shipping to replace damaged products rapidly, which additionally strains their spending plans. Eventually, disregarding stretch wrapper fixings not only boosts prompt product packaging prices yet can likewise contribute to long-term economic instability, affecting productivity and competitiveness out there.

Downtime and Efficiency Loss

Downtime positions a significant danger to functional effectiveness in any type of company counting on stretch wrappers. When these equipments experience breakdowns, production halts, leading to significant efficiency losses. Each hour of inactivity not only threatens operations yet likewise increases labor prices as employees stay still. Furthermore, postponed shipments can harm customer partnerships and taint a company's reputation. The financial effects are profound; disregarding prompt fixings can bring about collective losses that much go beyond the expense of maintenance. By focusing on stretch wrapper maintenance, organizations can minimize downtime, improve efficiency, and assurance consistent operational flow. Inevitably, investing in routine repair work safeguards earnings and sustains competitive benefit in a demanding market.

Indicators That Your Stretch Wrapper Needs Maintenance

How can one inform when a stretch wrapper calls for upkeep? A number of indications suggest that a stretch wrapper may not be running at peak performance. Initially, irregular wrapping stress might result in extremely tight or loosened tons, compromising bundle stability. Additionally, if the equipment creates excessive sound or vibrations throughout procedure, it might represent worn components that require interest. Operators needs to likewise observe the film's application; if there are splits or wrinkles, this could point to issues with the film carriage or the stress settings.Frequent mistake messages or alarms throughout operation are an additional clear sign of potential problems. Moreover, if the cycle time rises, it might recommend that the stretch wrapper is battling to perform at its finest. Consistently checking for these indications can assist ensure that maintenance is scheduled prior to more considerable issues arise, ultimately adding to the total efficiency of the product packaging process.

Advantages of Regular Stretch Wrapper Maintenance

Regular maintenance of stretch wrappers provides substantial benefits for packaging operations. It not just prolongs the lifespan of the devices yet also lessens downtime prices and boosts the general high quality of packaging. By prioritizing maintenance, companies can enhance performance and warranty regular efficiency in their packaging processes.

Enhanced Tools Life-span

Maintaining a stretch wrapper not only improves product packaging effectiveness however also significantly prolongs the tools's life expectancy. Routine upkeep techniques, such as cleaning, lubrication, and timely replacement of used parts, prevent early damage, ensuring that the equipment operates at peak performance. By dealing with small problems prior to they intensify, drivers can avoid significant damages that can lead to costly repair services or the requirement for a complete substitute. Additionally, consistent i was reading this maintenance fosters a far better understanding of the equipment's operational limits, enabling ideal usage without overexertion. This aggressive approach inevitably contributes to a longer operational life for the stretch wrapper, making the most of the roi for companies and guaranteeing dependability in their packaging procedures.

Reduced Downtime Expenses

Effective procedures depend upon lessening downtime, specifically in high-demand product packaging settings. Normal maintenance of stretch wrappers especially lowers the probability of unexpected failures, which can cause costly production stops. By proactively addressing small concerns before they rise into significant failings, companies can assure that their packaging lines stay operational. This precautionary approach not only saves time however also lowers labor prices related to emergency repairs and unexpected downtime. Furthermore, regular maintenance enables for better scheduling of repairs, resulting in less disruption throughout optimal operational hours. Therefore, the total productivity of the product packaging procedure improves, translating right into better efficiency and expense savings for the organization. Normal stretch wrapper upkeep is essential for keeping functional consistency in open markets.

Improved Product Packaging Quality

When stretch wrappers are appropriately preserved, get more the quality of product packaging can considerably enhance, ensuring that products are securely wrapped and shielded during transit and storage space. Regular maintenance helps in identifying and remedying potential issues prior to they rise, such as misalignment or wear on components, which can jeopardize the covering process. This positive technique not only enhances the stability of the covered products but also minimizes the danger of damages triggered by ecological elements. Furthermore, constantly well-maintained stretch wrappers contribute to uniformity in packaging, making sure that each tons fulfills the required requirements. Ultimately, enhanced product packaging high quality leads to boosted consumer satisfaction, decreased return rates, and a stronger online reputation for integrity, every one of which are important for continual organization success.

Choosing the Right Repair Service Service for Your Stretch Wrapper

Picking the proper fixing service for a stretch wrapper is essential to keeping packaging performance and minimizing downtime. Organizations should prioritize solutions that specialize in stretch wrapper repairs, as these service providers possess the needed know-how and experience. Evaluating the specialist's certifications and the company's credibility can substantially affect repair quality.Additionally, it is useful to take into consideration the schedule of substitute parts and the rate of service. A dependable repair solution ought to not only supply punctual assistance however likewise supply warranty choices for their job, ensuring lasting self-confidence in repairs.Furthermore, companies must choose reviews and evaluations from various other clients to assess the solution's efficiency and reliability. Transparent interaction regarding prices and repair work timelines is likewise necessary in establishing count on. Ultimately, selecting the best repair solution can lead to enhanced functional effectiveness, lowered prices, and improved productivity for organizations counting on stretch wrappers for their product packaging requires.

Best Practices for Stretch Wrapper Maintenance and Longevity

Regular maintenance is important for ensuring the long life and ideal performance of stretch wrappers. Consistent examinations should be conducted to identify deterioration on parts, such as rollers, motors, and belts. Lubing relocating parts at recommended intervals lessens rubbing and prolongs tools life.Furthermore, drivers need to be trained to use the equipment appropriately, as incorrect handling can lead to early failures. Maintaining the work space free and tidy of debris decreases the threat of mechanical damage and advertises a secure working environment.Replacing worn or damaged components immediately is crucial; this stops minor problems from intensifying right into pricey repairs. Additionally, keeping a log of maintenance activities aids track the efficiency and service background of the stretch wrapper.

Regularly Asked Questions

Just How Commonly Should Stretch Wrappers Be Serviced for Optimum Performance?

The regularity of servicing stretch wrappers typically relies on usage strength. Typically, producers recommend examinations every 6 to 12 months, making sure peak performance and lessening unintended downtime with proactive upkeep and timely repair work.

Can I Carry Out Repairs on Stretch Wrappers Myself?

The individual contemplated whether they can perform repair services on stretch wrappers themselves. stretch wrapper repair. It was noted that while some minor modifications might be convenient, professional proficiency is commonly suggested for complex problems to assure security and performance

What Components of a Stretch Wrapper Are Most Prone to Failure?

Stretch wrappers typically experience failures in elements such as the film carriage, drive electric motors, and sensing units. These parts are essential to the machine's procedure and may need routine upkeep or prompt replacement to guarantee peak efficiency.

Exactly How Does Environmental Effect Impact Stretch Wrapper Performance?

Ecological factors, such as moisture and temperature variations, can significantly affect stretch wrapper performance. These conditions might cause material destruction, inconsistent covering tension, and inevitably, reduced efficiency in the you can try here packaging process. Regular evaluations are necessary.

Exist Specific Brands Understood for Better Longevity in Stretch Wrappers?